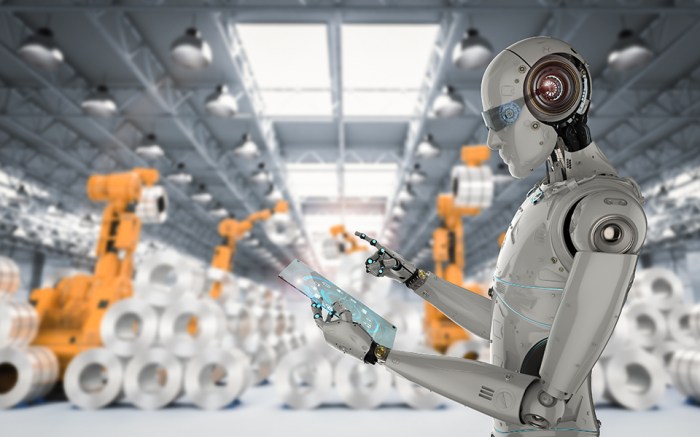

Yo, diving into the world of AI in industrial automation, where innovation meets efficiency in a dope fusion. Get ready to explore the cutting-edge tech shaping the future of industries.

From enhancing productivity to streamlining costs, AI is the game-changer every industrial player needs. Let’s break down the buzz around AI in automation.

Overview of AI in Industrial Automation

AI plays a crucial role in industrial automation by utilizing advanced technologies to enhance efficiency, productivity, and cost-effectiveness in manufacturing processes. These technologies are transforming industrial processes by enabling machines to make intelligent decisions and adapt to changing conditions. Examples of AI applications in automation include predictive maintenance, quality control, and autonomous robots.

Benefits of Implementing AI in Industrial Automation

Implementing AI in industrial automation offers numerous advantages such as improved efficiency, increased productivity, and cost savings. When compared to traditional automation methods, AI-powered automation provides more accurate and adaptive solutions, leading to better decision-making and optimized operations. The integration of AI technologies results in significant improvements in efficiency, productivity, and cost-effectiveness in industrial settings.

AI Technologies Used in Industrial Automation

Various AI technologies are commonly used in industrial automation, including machine learning algorithms that enhance automation processes by learning from data and making predictions. Computer vision is utilized for visual inspection and monitoring tasks, while natural language processing enables machines to understand and respond to human language in industrial settings.

Challenges and Limitations of AI in Industrial Automation

Challenges faced when implementing AI in industrial automation include data quality issues, integration complexities, and the need for skilled professionals to manage AI systems. Limitations of AI technologies in complex industrial environments involve scalability issues, interpretability of AI decisions, and potential biases in algorithms. Risks associated with AI integration in automation include cybersecurity threats, job displacement, and ethical concerns.

Case Studies of Successful AI Implementation in Industrial Automation

Real-world examples of companies benefiting from AI in industrial automation include predictive maintenance systems reducing downtime, quality control processes improving product consistency, and autonomous robots enhancing operational efficiency. AI has significantly improved safety standards in industrial settings by identifying potential hazards and preventing accidents. AI-driven predictive maintenance has revolutionized manufacturing processes by predicting equipment failures before they occur, leading to cost savings and increased reliability.